HVAC

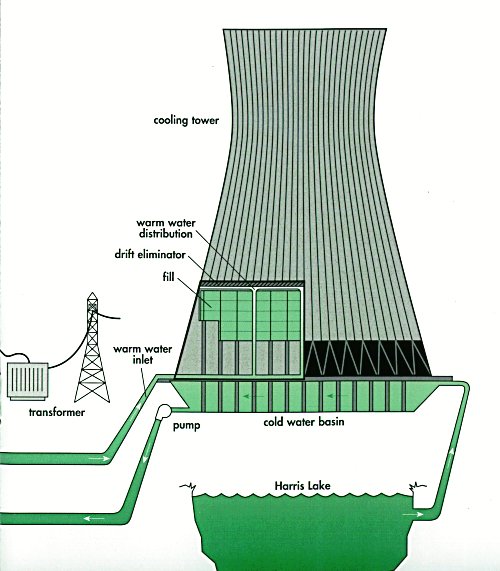

An HVAC cooling tower is a subcategory rejecting heat from a chiller. Water-cooled chillers are normally more energy efficient than air-cooled chillers due to heat rejection to tower water at or near wet-bulb temperatures. Air-cooled chillers must reject heat at the dry-bulb temperature, and thus have a lower average reverse-Carnot cycle effectiveness. Large office buildings, hospitals, and schools typically use one or more cooling towers as part of their air conditioning systems. Generally, industrial cooling towers are much larger than HVAC towers.

HVAC use of a cooling tower pairs the cooling tower with a water-cooled chiller or water-cooled condenser.A ton of air-conditioning is the removal of 12,000 Btu/hour (3517 W). The equivalent ton on the cooling tower side actually rejects about 15,000 Btu/hour (4396 W) due to the heat-equivalent of the energy needed to drive the chiller's compressor. This equivalent ton is defined as the heat rejection in cooling 3 U.S. gallons/minute (1,500 pound/hour) of water 10 °F (5.56 °C), which amounts to 15,000 Btu/hour, or a chiller coefficient performance (COP) of 4.0. This COP is equivalent to an energy efficiency ratio (EER) of 13.65.

Cooling towers are also used in HVAC systems that have multiple water source heat pumps that share a common piping "water loop". In this type of system, the water circulating inside the "water loop" removes heat from the condenser of the heat pumps whenever the heat pumps are working in the cooling mode, then the cooling tower is used to remove heat from the water loop and reject it to the atlmosphere. When the heat pumps are working in heating mode, the condensers draw heat out of the loop water and reject it into the space to be heated.

Heat transfer methods

With respect to the heat transfer mechanism employed, the main types are:

- Wet cooling towers or simply open circuit cooling towers operate on the principle of evaporation. The working fluid and the evaporated fluid (usually H2O) are one and the same.

- Dry Cooling Towers operate by heat transfer through a surface that separates the working fluid from ambient air, such as in a tube to air heat exchanger, utilizing convective heat transfer. They do not use evaporation.

- Fluid coolers or Closed Circuit Cooling Towers are hybrids that pass the working fluid through a tube bundle, upon which clean water is sprayed and a fan-induced draft applied. The resulting heat transfer performance is much closer to that of a wet cooling tower, with the advantage provided by a dry cooler of protecting the working fluid from environmental exposure and contamination.

In a wet cooling tower (or Open Circuit Cooling Tower), the warm water can be cooled to a temperature lower than the ambient air dry-bulb temperature, if the air is relatively dry. (see: dew point and psychrometrics). As ambient air is drawn past a flow of water, an small portion of the water evaporate, the energy required by that portion of the water to evaporate is taken from the remaining mass of water reducing his temperature (aproximately by 970 BTU for each pound of evaporated water). Evaporation results in saturated air conditions, lowering the temperature of the water process by the tower to a value close to wet bulb air temperature, which is lower than the ambient dry bulb air temperature, the difference determined by the humidity of the ambient air.

To achieve better performance (more cooling), a medium called fill is used to increase the surface area and the time of contact between the air and water flows. Splash fill consists of material placed to interrupt the water flow causing splashing. Film fill is composed of thin sheets of material (usually PVC) upon which the water flows. Both methods create increased surface area and time of contact between the fluid (water) and the gas (air).

Air flow generation methods

With respect to drawing air through the tower, there are three types of cooling towers:

- Natural Draft, which utilizes buoyancy via a tall chimney. Warm, moist air naturally rises due to the density differential to the dry, cooler outside air. Warm moist air is less dense than drier air at the same pressure. This moist air buoyancy produces a current of air through the tower.

- Mechanical draft, which uses power driven fan motors to force or draw air through the tower.

- Induced draft: A mechanical draft tower with a fan at the discharge which pulls air through tower. The fan induces hot moist air out the discharge. This produces low entering and high exiting air velocities, reducing the possibility of recirculation in which discharged air flows back into the air intake. This fan/fin arrangement is also known as draw-through. (see Image 2, 3)

- Forced draft: A mechanical draft tower with a blower type fan at the intake. The fan forces air into the tower, creating high entering and low exiting air velocities. The low exiting velocity is much more susceptible to recirculation. With the fan on the air intake, the fan is more susceptible to complications due to freezing conditions. Another disadvantage is that a forced draft design typically requires more motor horsepower than an equivalent induced draft design. The forced draft benefit is its ability to work with high static pressure. They can be installed in more confined spaces and even in some indoor situations. This fan/fill geometry is also known as blow-through. (see Image 4)

- Fan assisted natural draft. A hybrid type that appears like a natural draft though airflow is assisted by a fan.

Hyperboloid (a.k.a. hyperbolic) cooling towers (Image 1) have become the design standard for all natural-draft cooling towers because of their structural strength and minimum usage of material. The hyperboloid shape also aids in accelerating the upward convective air flow, improving cooling efficiency. They are popularly associated with nuclear power plant. However, this association is misleading, as the same kind of cooling towers are often used at large coal-fired power plants as well. Similarly, not all nuclear power plants have cooling towers, instead cooling their heat exchangers with lake, river or ocean water.